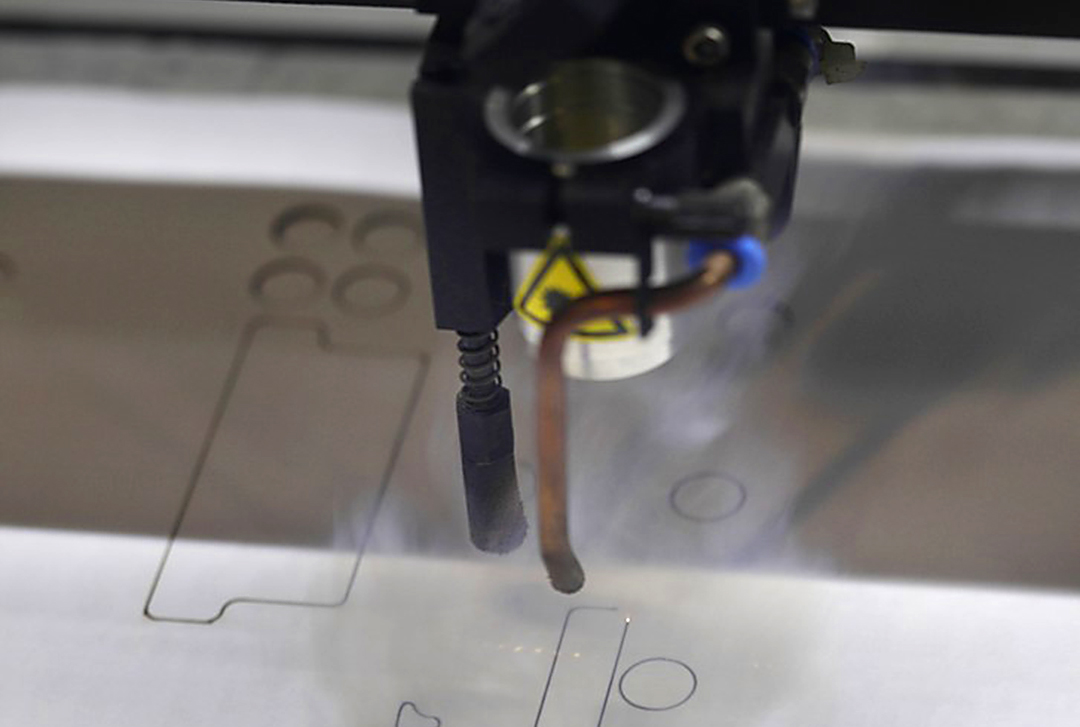

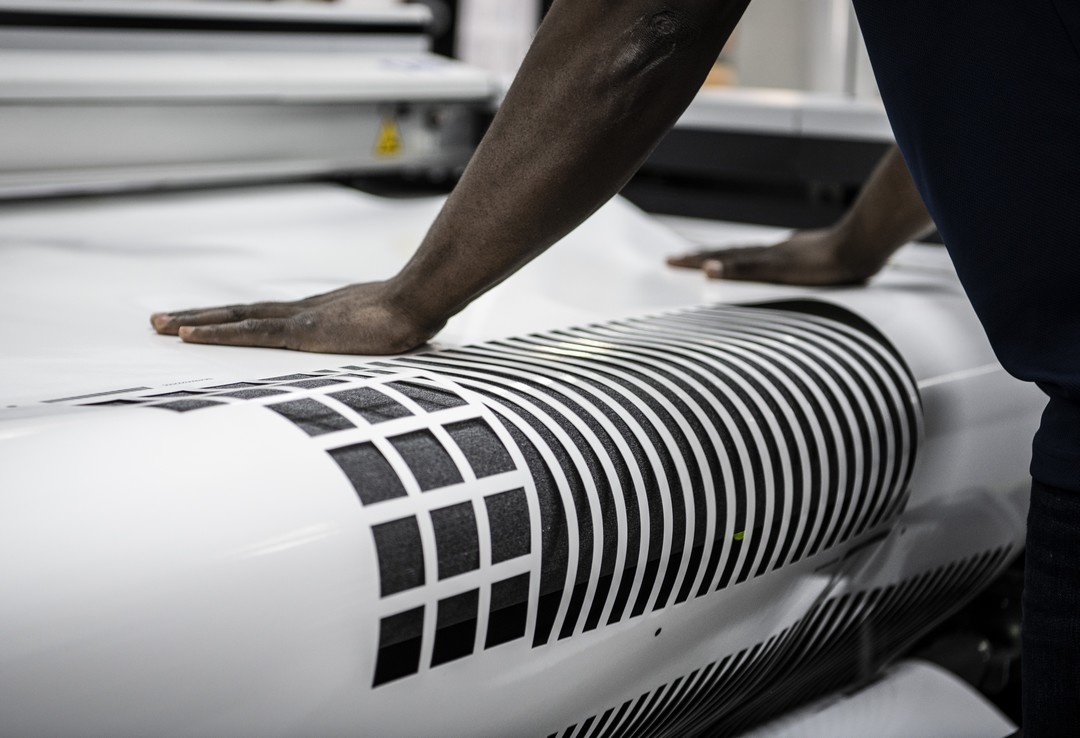

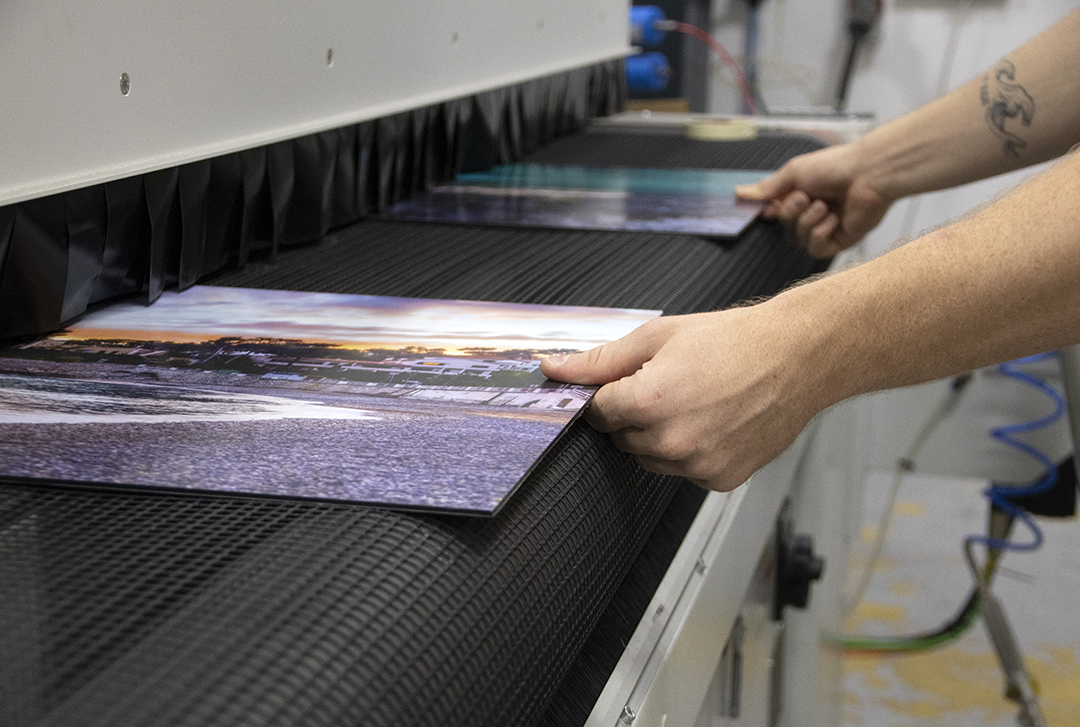

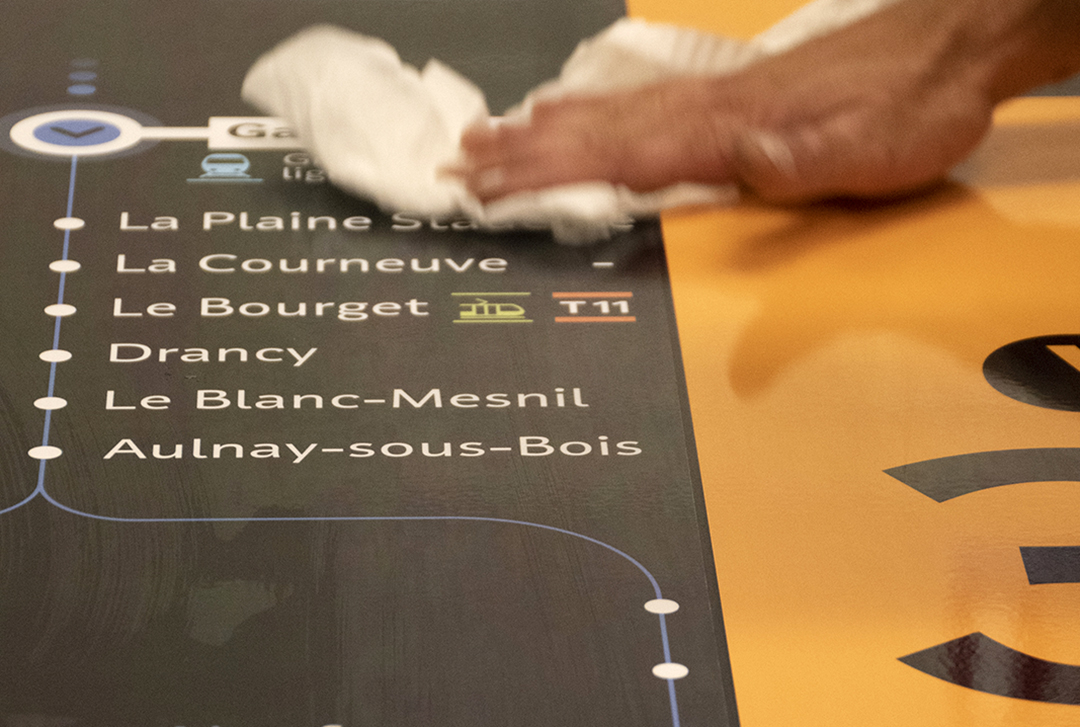

Cutting, Engraving and Finishing

Machining & forming

For a quality finish, Oxy has high-precision equipment, expertise with different materials (aluminium, PVC, stainless steel, Gravoply, steel, composite materials, wood, etc.) and offers a wide range of possibilities, including coating, surfacing, mechanical cutting, digital cutting, sticker cutting and thermoforming. Our team’s expertise and professionalism make all the difference.